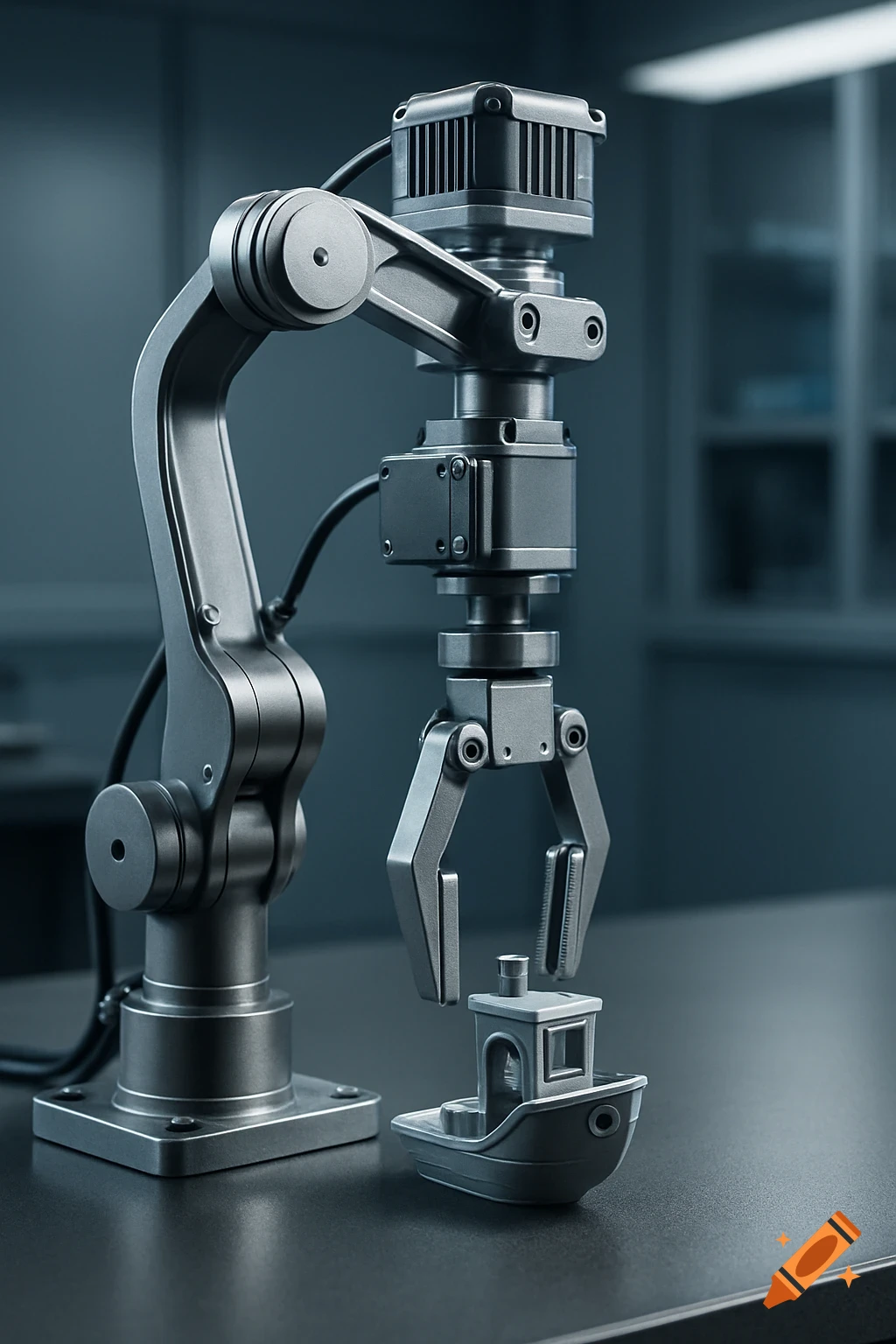

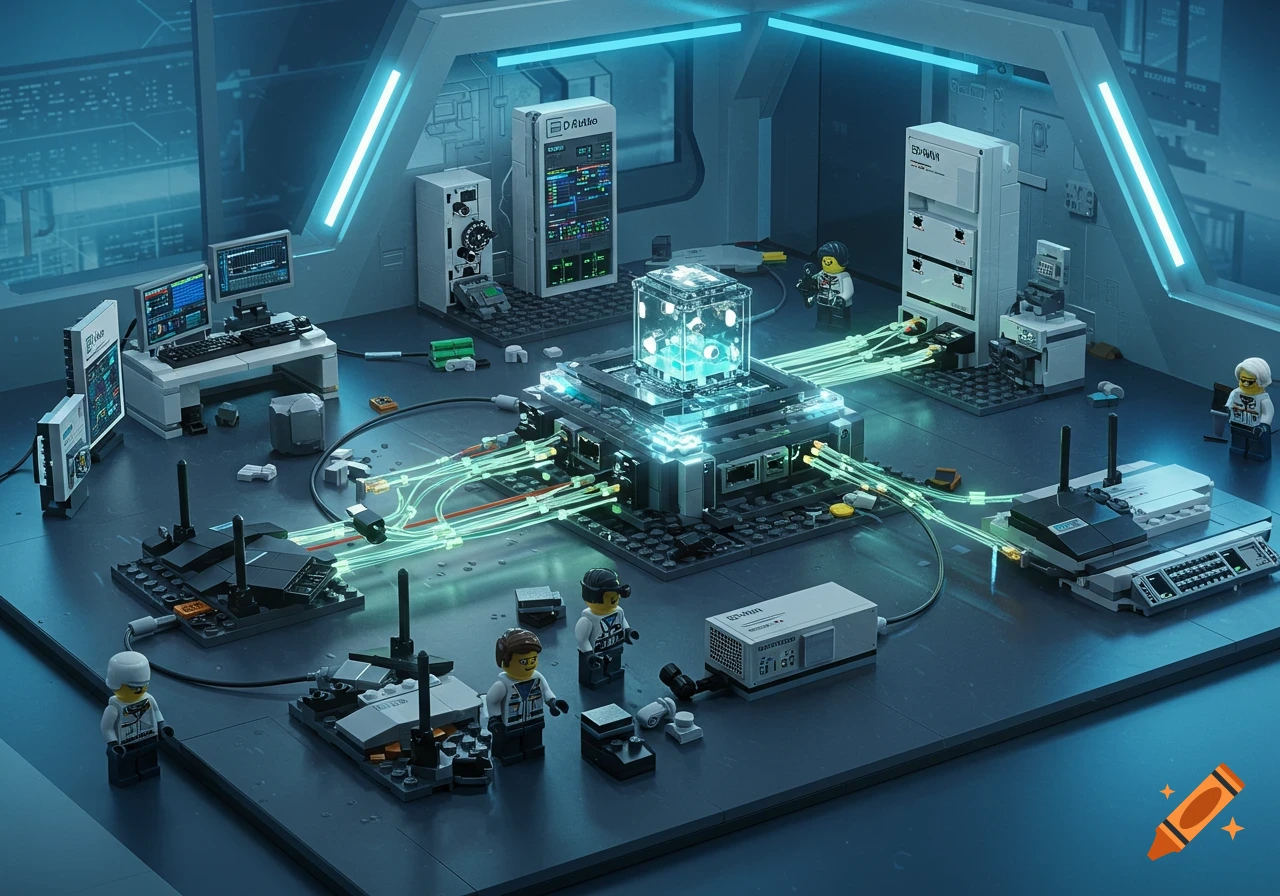

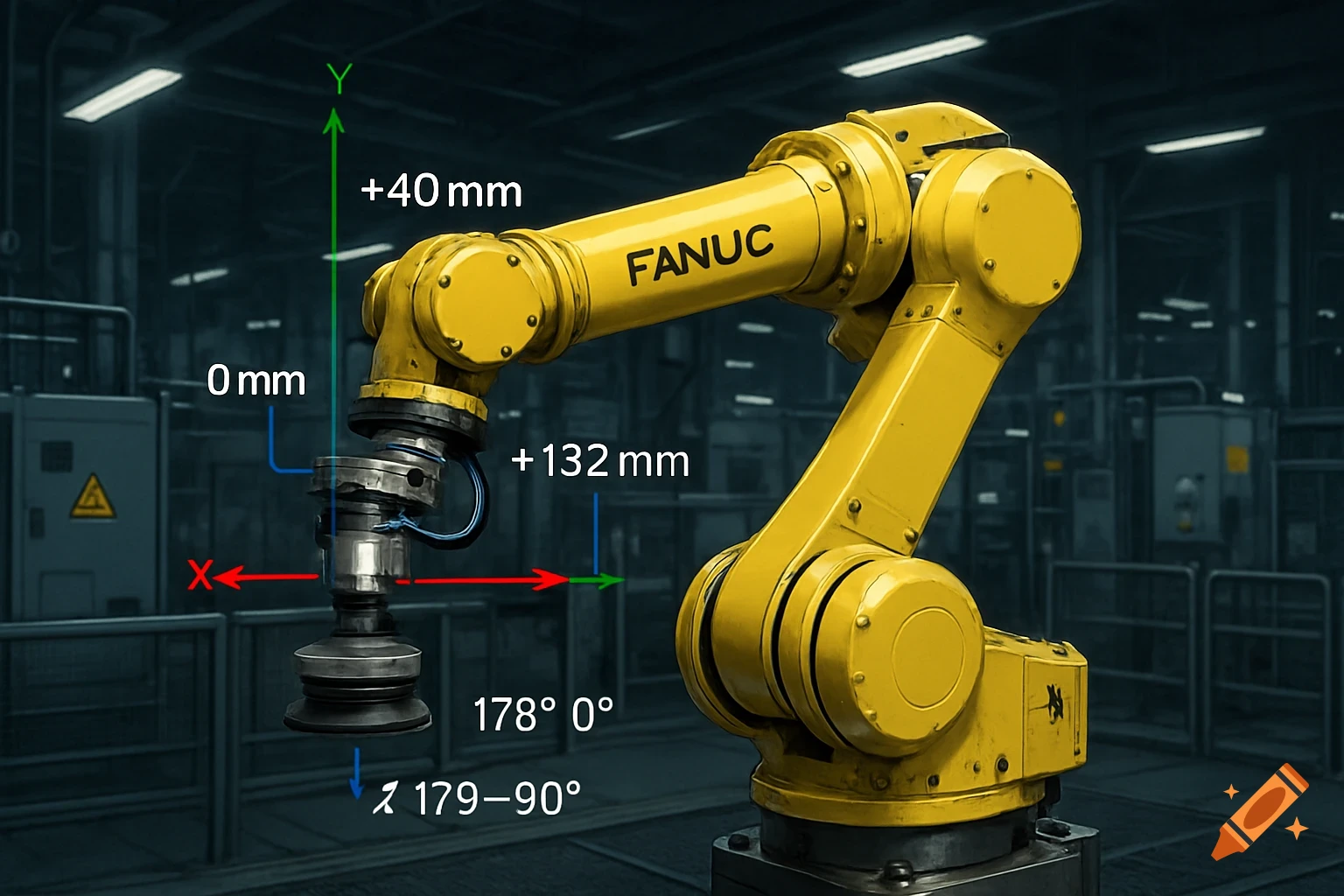

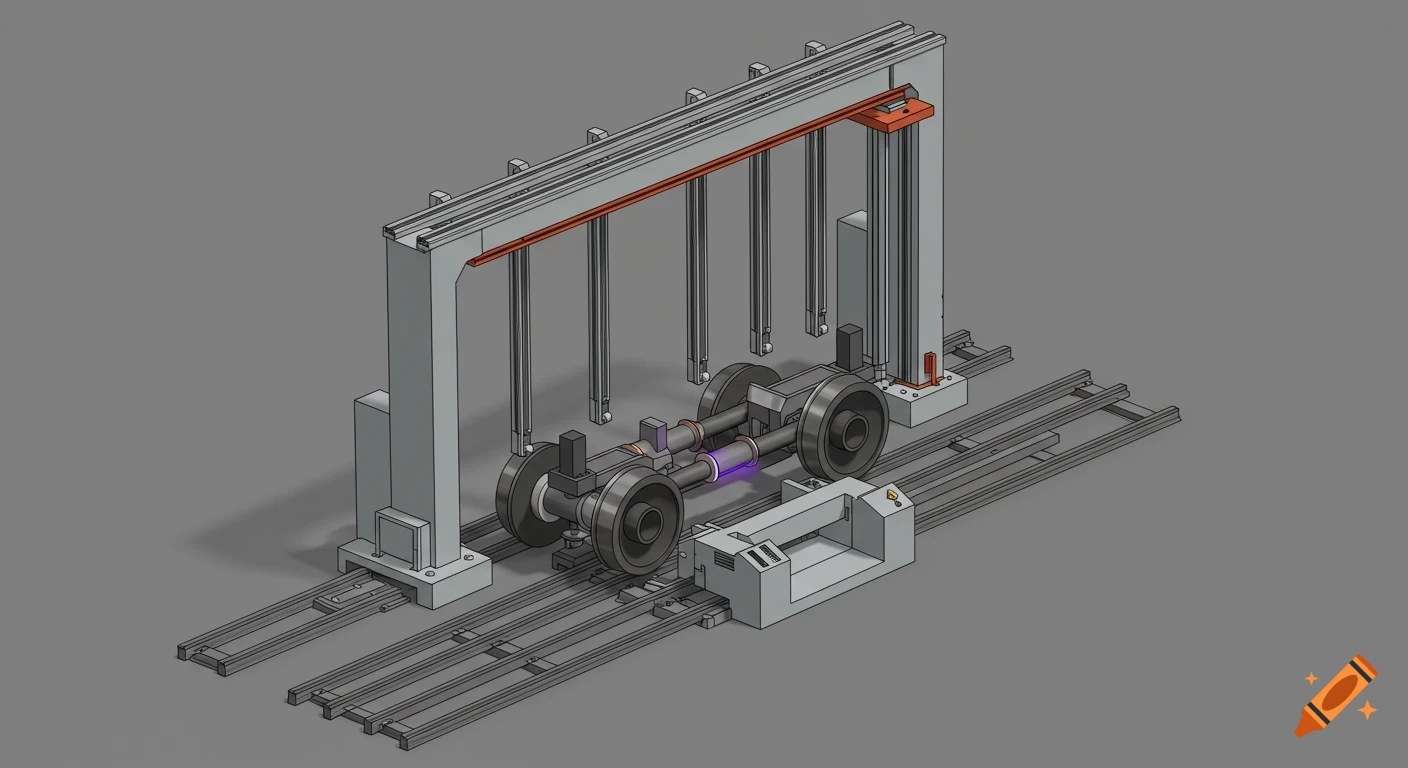

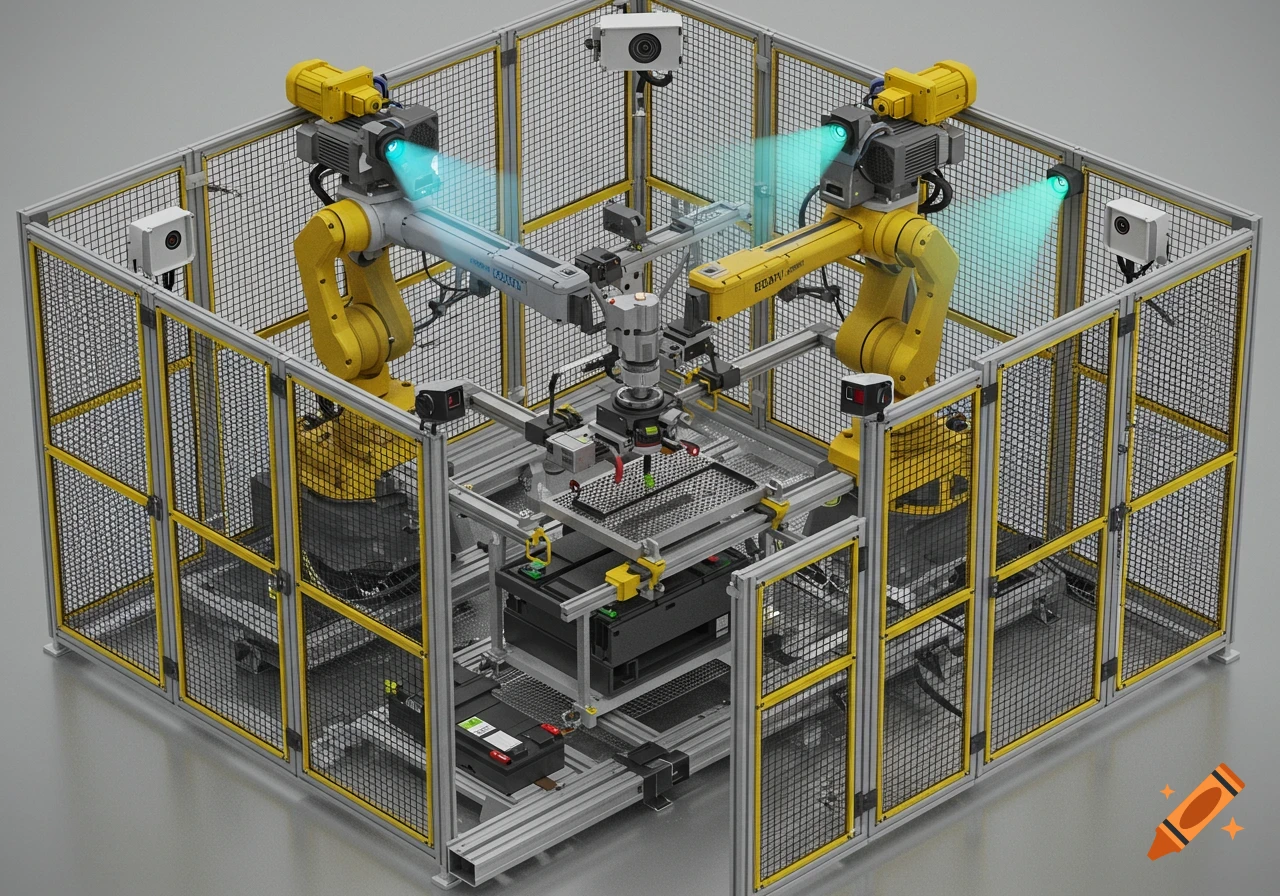

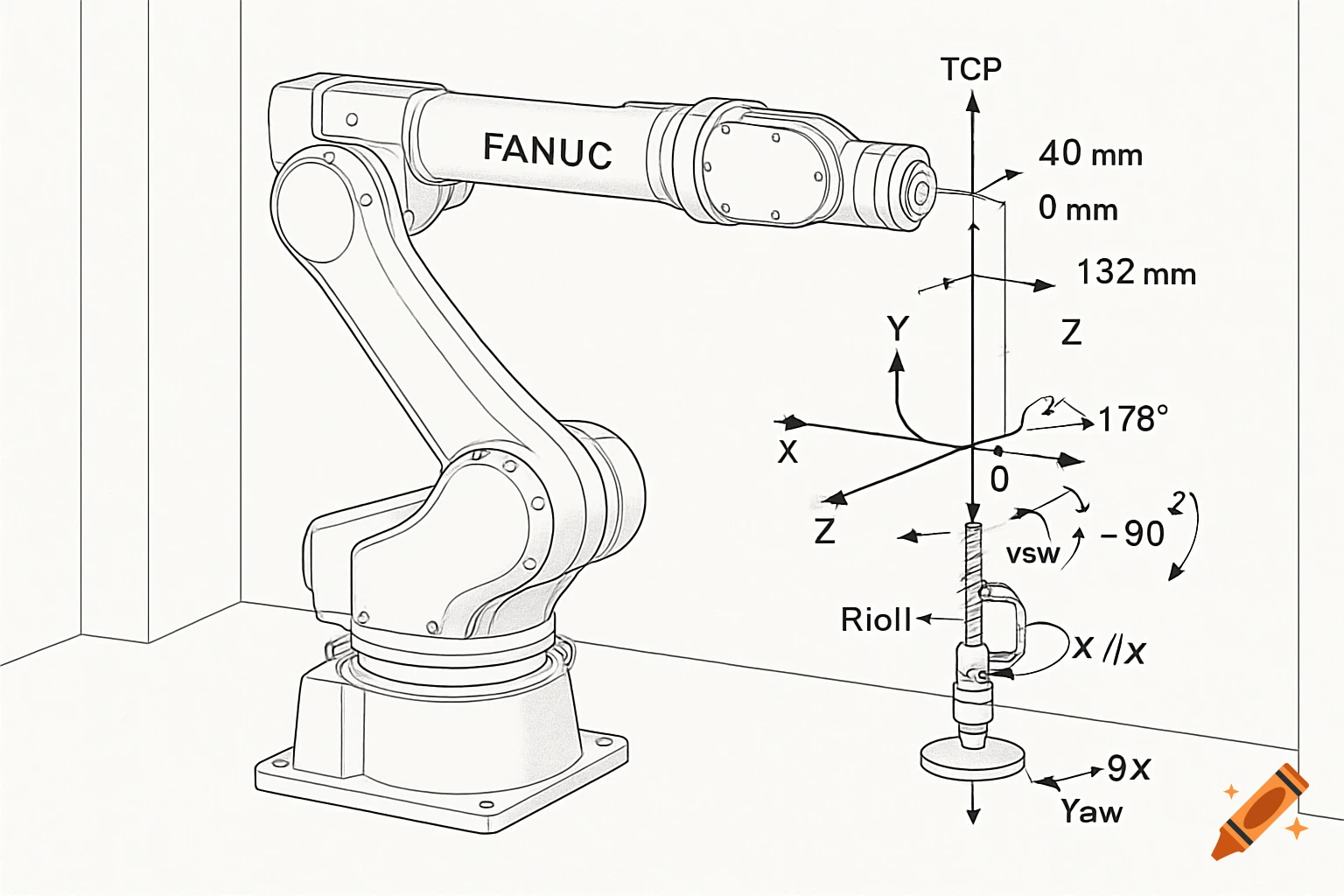

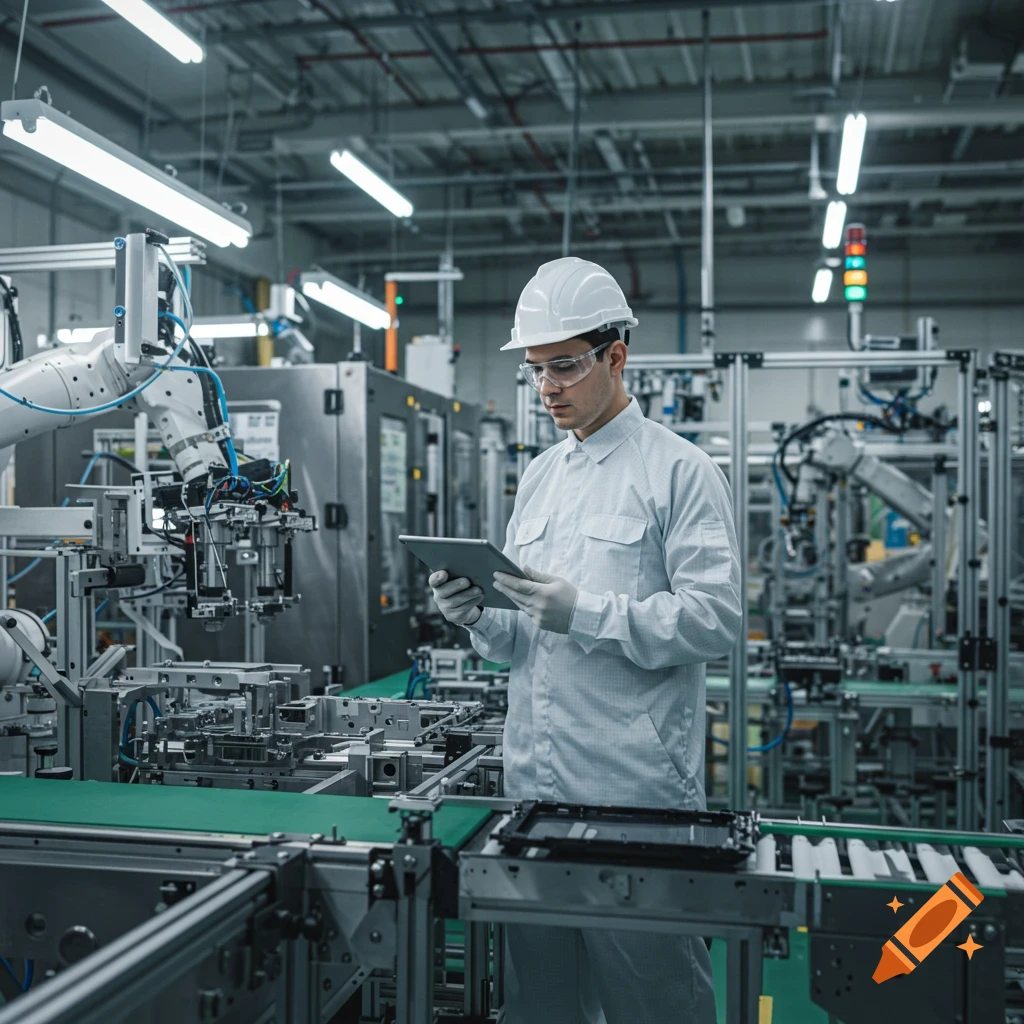

A white robotic arm in an industrial automation setup with labeled zones: Input, Processing, Inspection, and Control. A hand holds a control pendant.

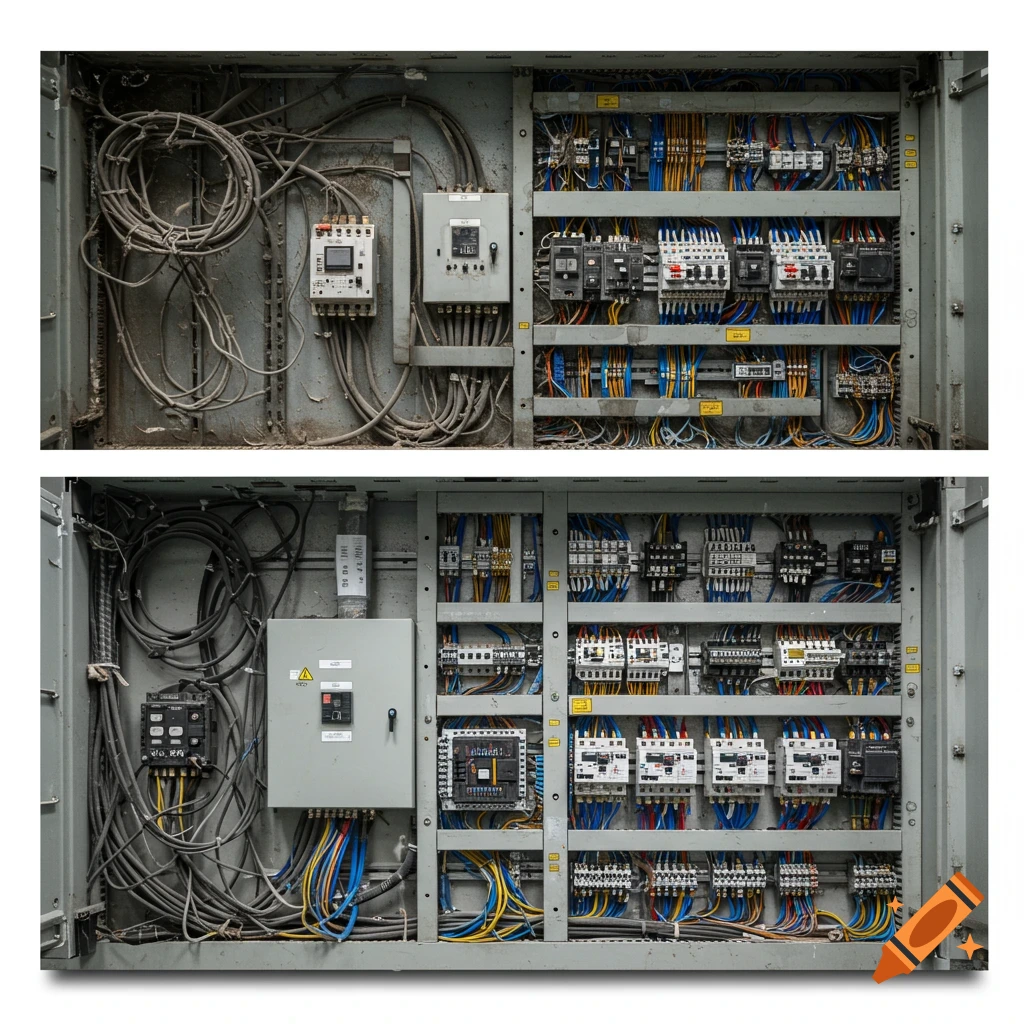

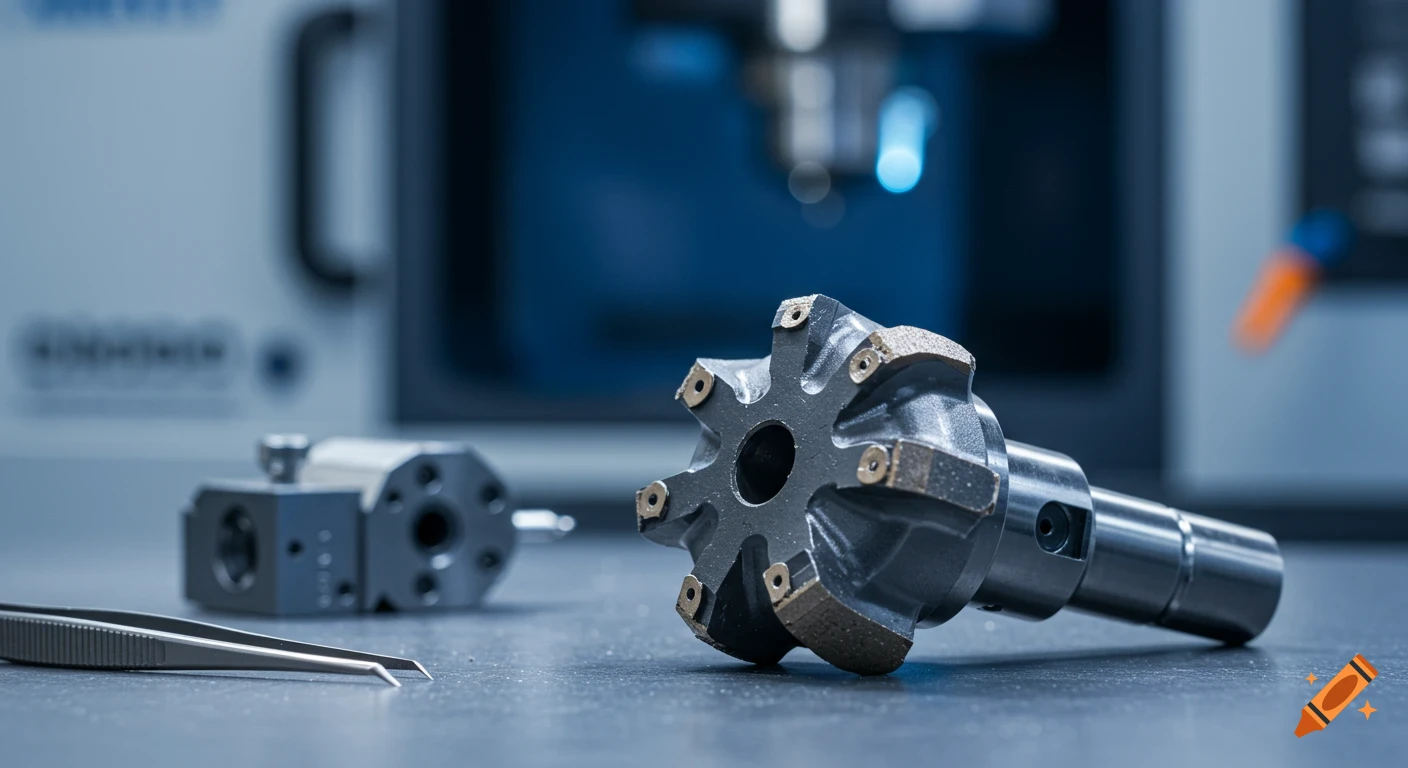

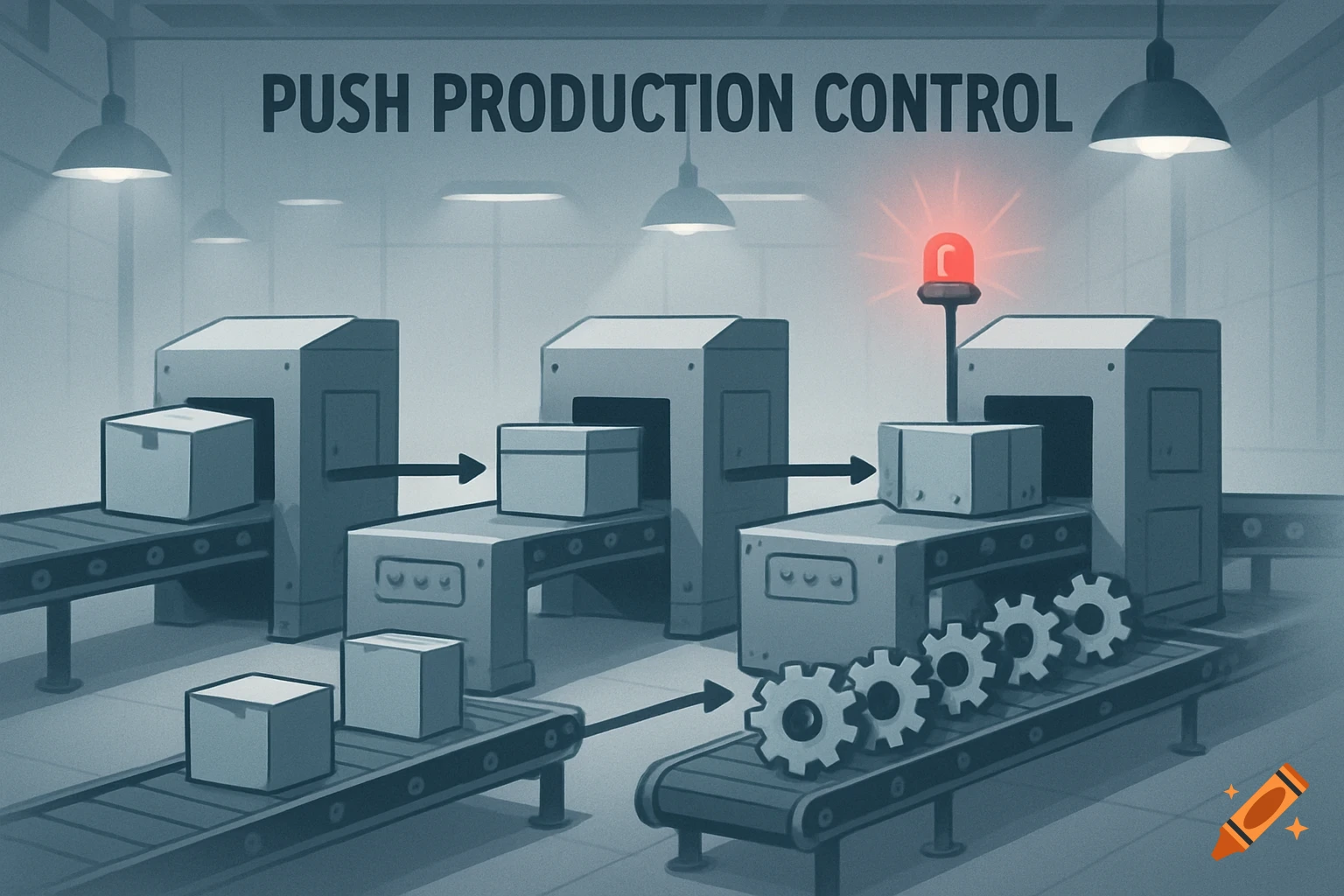

🧩 Conceptual Zones Zone Function Input Zone Entry point for raw parts Processing Zone Robot performs manipulation or assembly Inspection Zone Visual and force-based quality checks Control Zone Operator interaction via HMI & pendant 🔄 Process Flow Start Operator initiates the cycle using the Teach Pendant or Smart Tool. Pick The FR5 Cobot activates the Gripper EPG40-050 to grasp the workpiece from the Input Zone. Place The robot places the part onto the Magnetic Workpiece Holder in the Inspection Zone. Inspect The Orbbec Gemini 2 Camera captures visual data (color, shape, presence), while the GZCX-6F Sensor measures contact force or weight. Decide The Smart Tool interprets inspection results: If OK → part is transferred to packaging or next station If NOK → part is discarded or sent for reprocessing End Robot completes the programmed sequence and sends an end-of-cycle signal. Feedback Operator receives real-time status updates via the HMI or Smart Tool. ⚙️ Mechanical Setup Mount robot with 4× M8 bolts (≥8.8 grade) Surface: Shock-proof, Aluminum ≥16 mm or Steel ≥10 mm Minimum space: 3 m × 3 m × 2 m, +500 mm buffer if end-load 🔌 Electrical Interfaces Power Supply: 24 V DC, 1.5 A I/O Ports: 8 Universal Digital I/O 8 Configurable Digital I/O 2 Analog I/O Button Box replaces joystick Uses digital inputs Safety key wired to protection inputs Let me know if you'd like this exported into a slide layout, formatted for Word, or visualized with diagrams. I can also help you build the See more