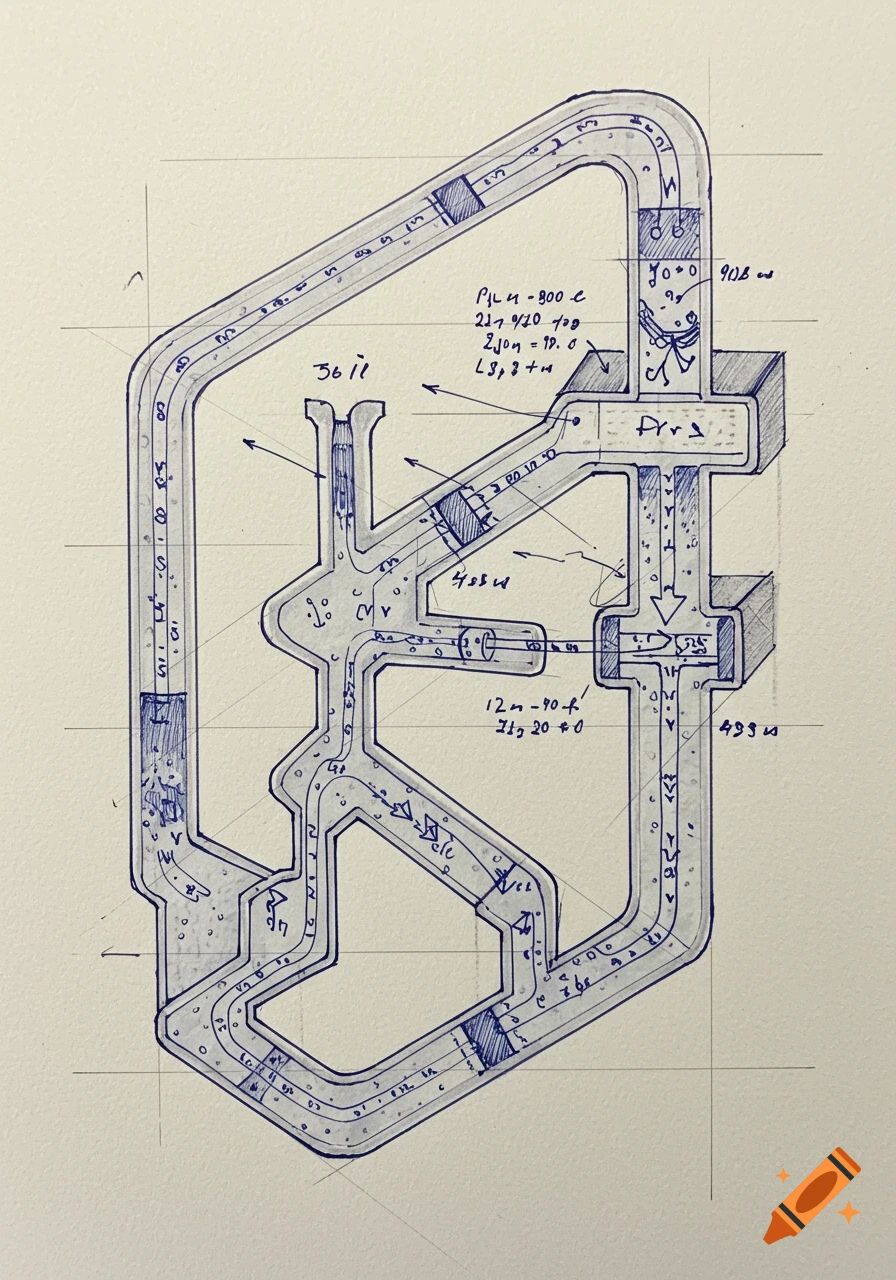

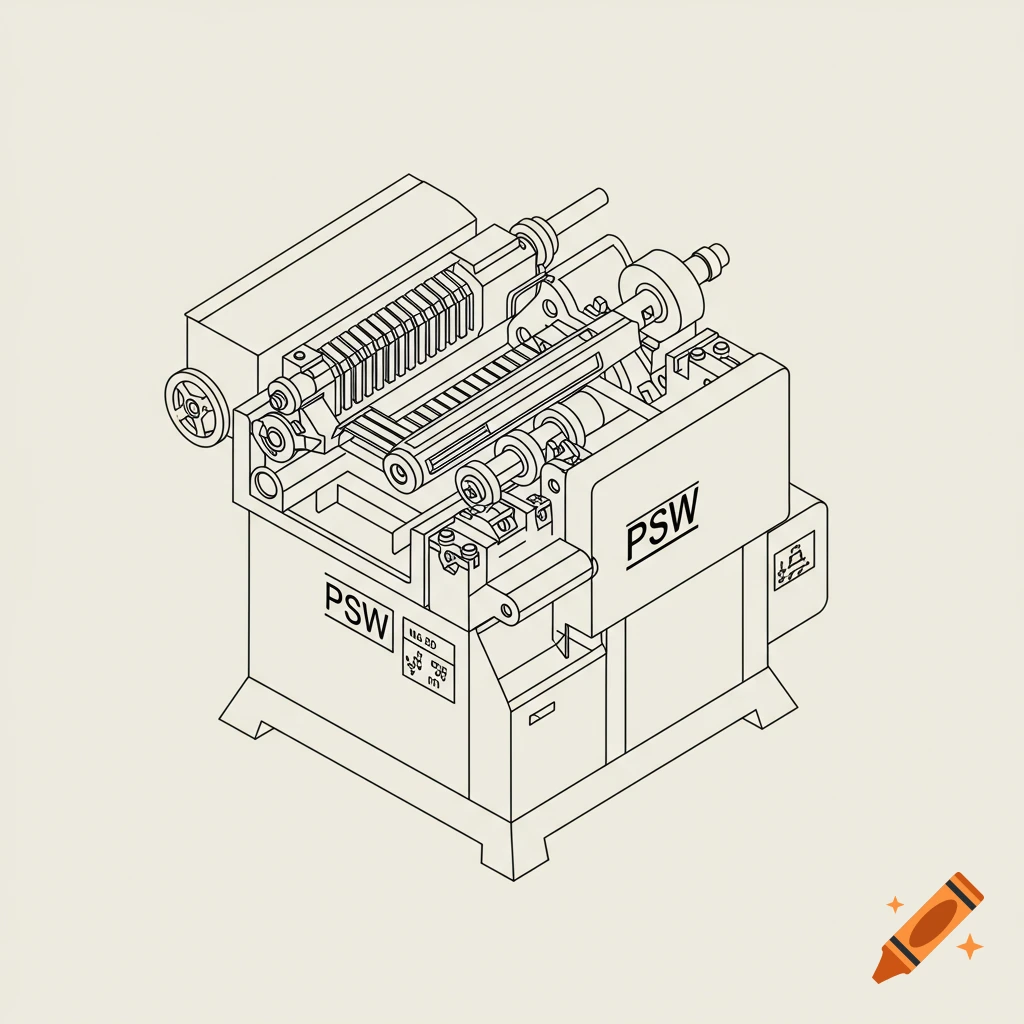

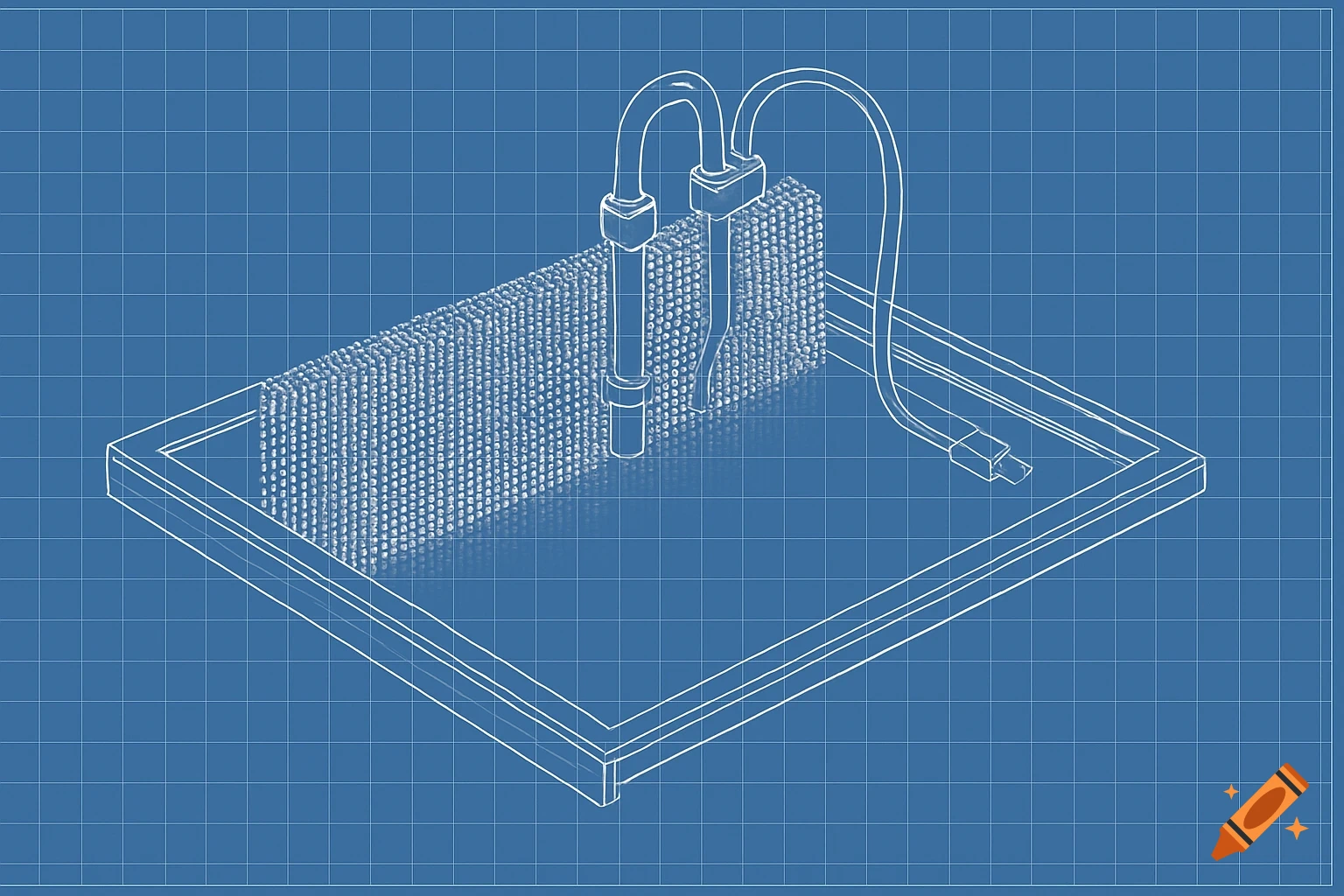

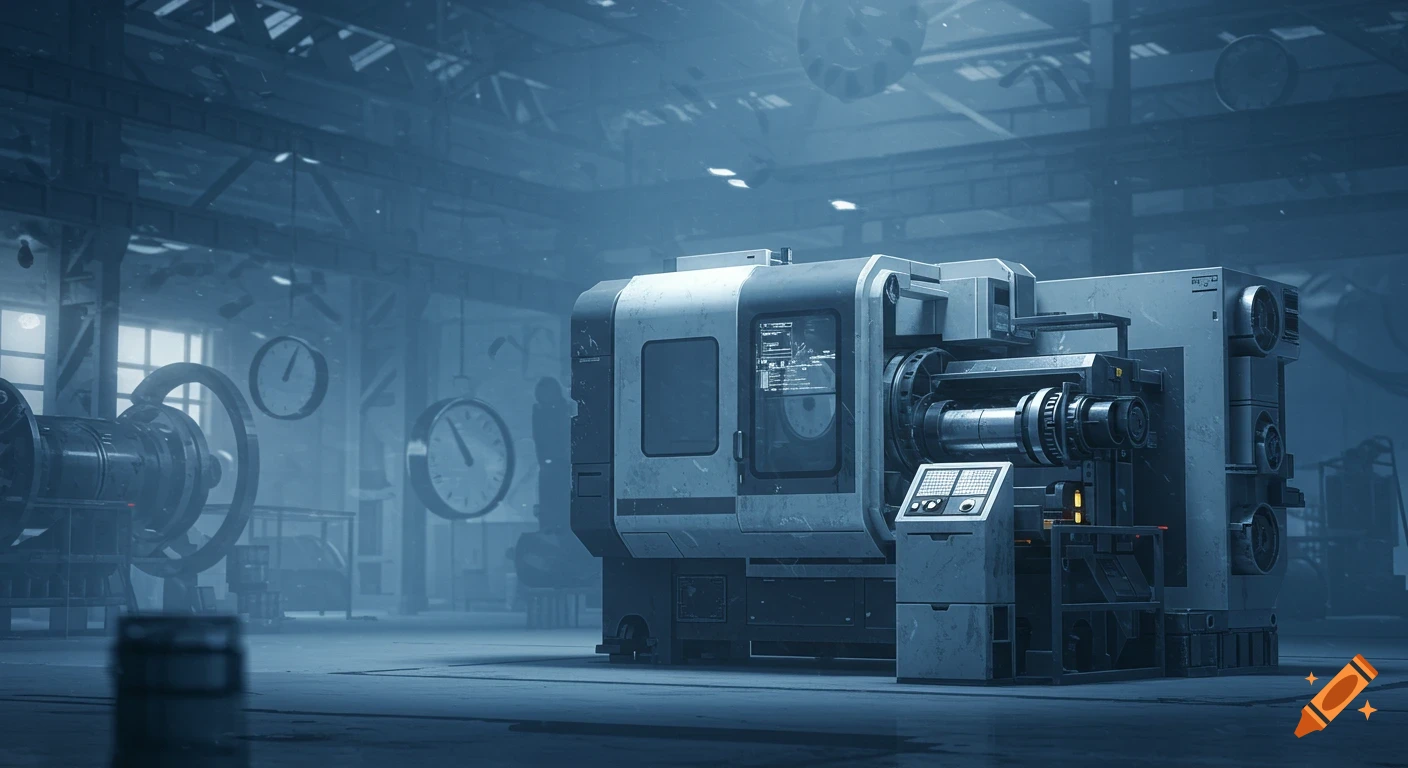

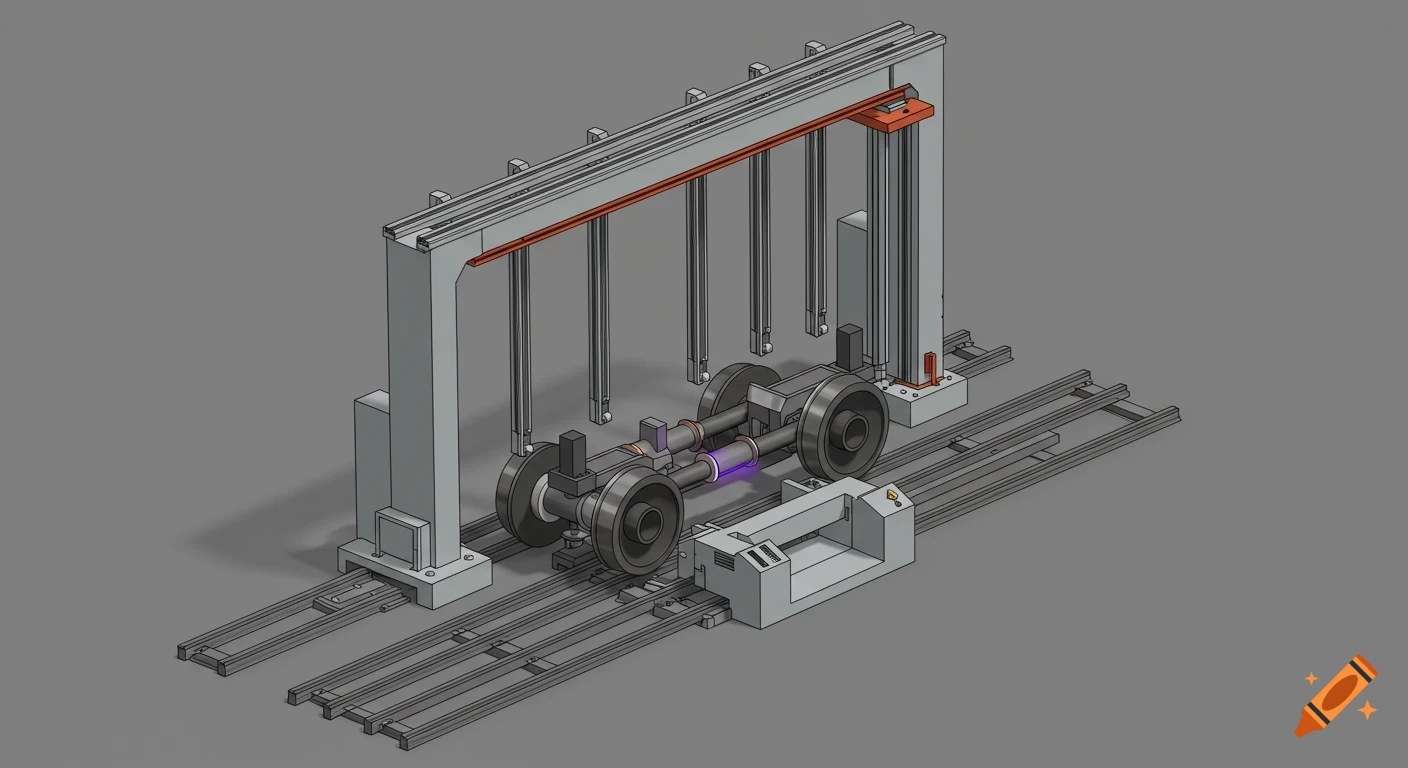

Isometric 3D render of a high-detail railway axle ultrasonic testing system with wheels on rollers and an overhead gantry.

High-detail isometric industrial 3D render of a railway axle ultrasonic testing system (Ultraschall-Vollwellenprüfstand). No text, no labels, no icons, no arrows, no people. Do not render any water. Scene & Composition One complete Radsatz (axle with two wheels) centered. Under the wheelset: a hydraulic rail pathway — two parallel steel tracks extending visibly beyond both sides (clear roll-in/roll-out path). In the center between the rails: a compact PID drive roller unit (Antriebseinheit); two drive rollers contact the wheel treads. The wheelset rests on the rollers (not floating). Hydraulic rail mechanics (must be visible) Integrate tilting/lifting rail sections with hinges and short hydraulic cylinders below/alongside the rails so the rails can dip to seat the wheelset onto the drive rollers (Einrollen) and rise to roll it out (Ausrollen). Stop arms at both ends of the central station: compact pivoting stoppers near the rails (geometry shows stop/open positions capability). Overhead Gantry — FRONT-FACE mounted Lanzes (strict) Rigid gantry: two vertical columns + one horizontal beam above the axle. On the FRONT FACE of the horizontal beam (NOT underneath/behind): exactly four long vertical Prüflanzen. Each Lanze is on its own horizontal linear carriage that slides left–right along a front-mounted linear guide rail (guide profile + slider blocks clearly modeled on the beam’s front face). Each Lanze shows three motions (readable by mechanics, no arrows): Horizontal travel See more