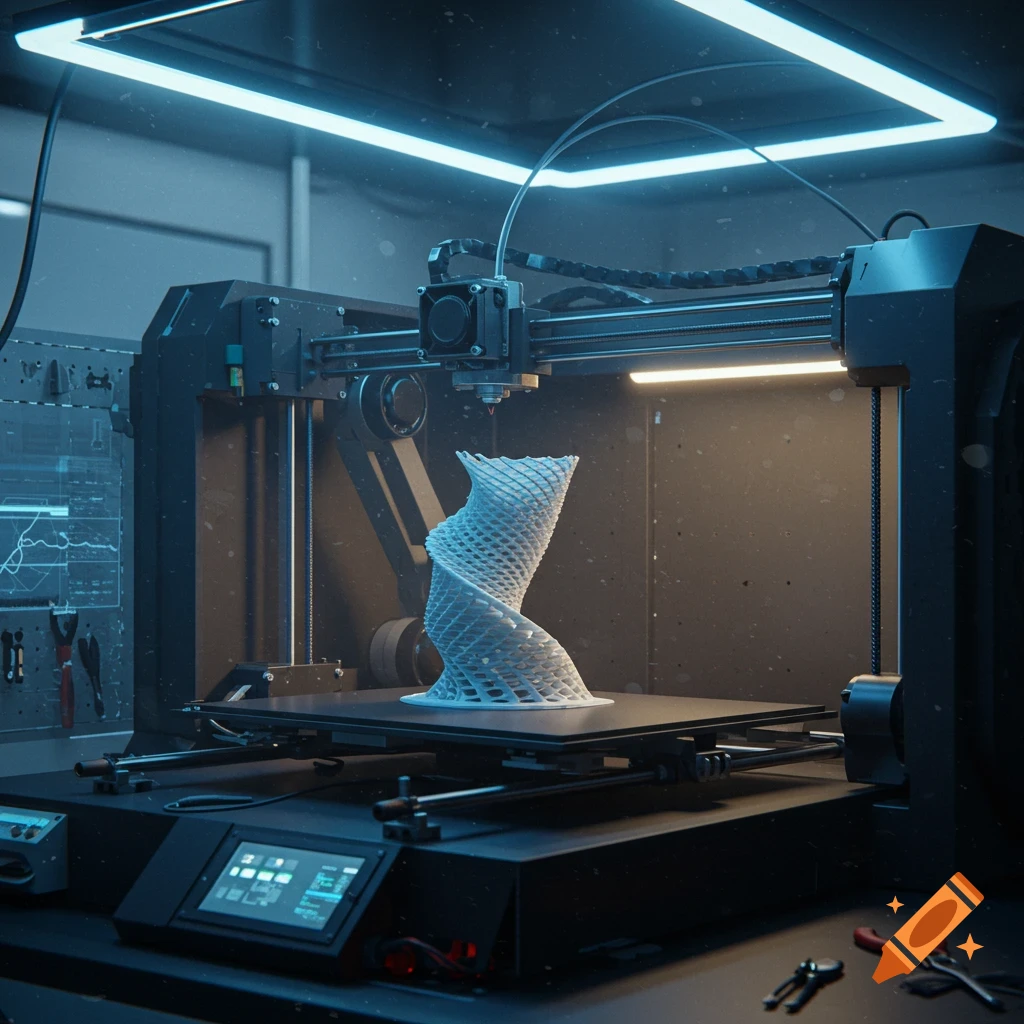

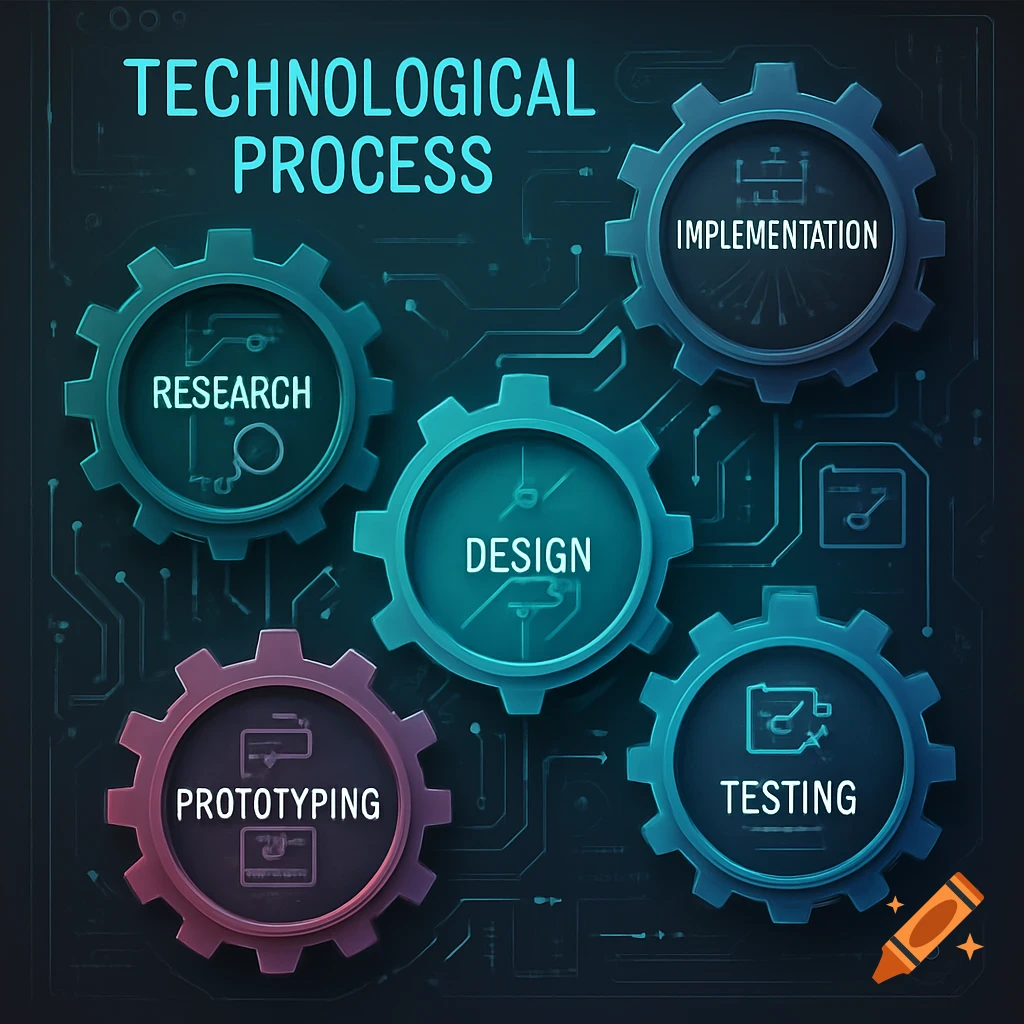

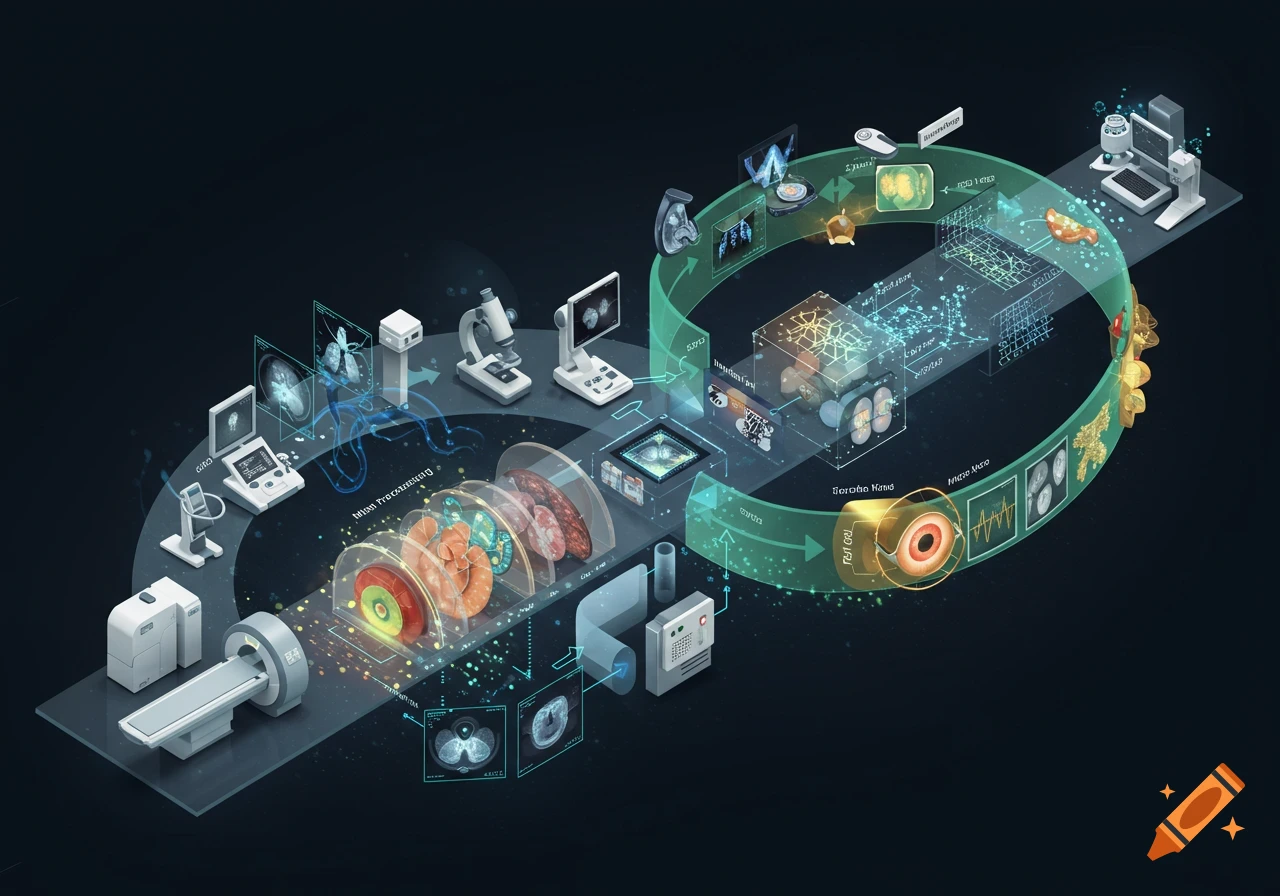

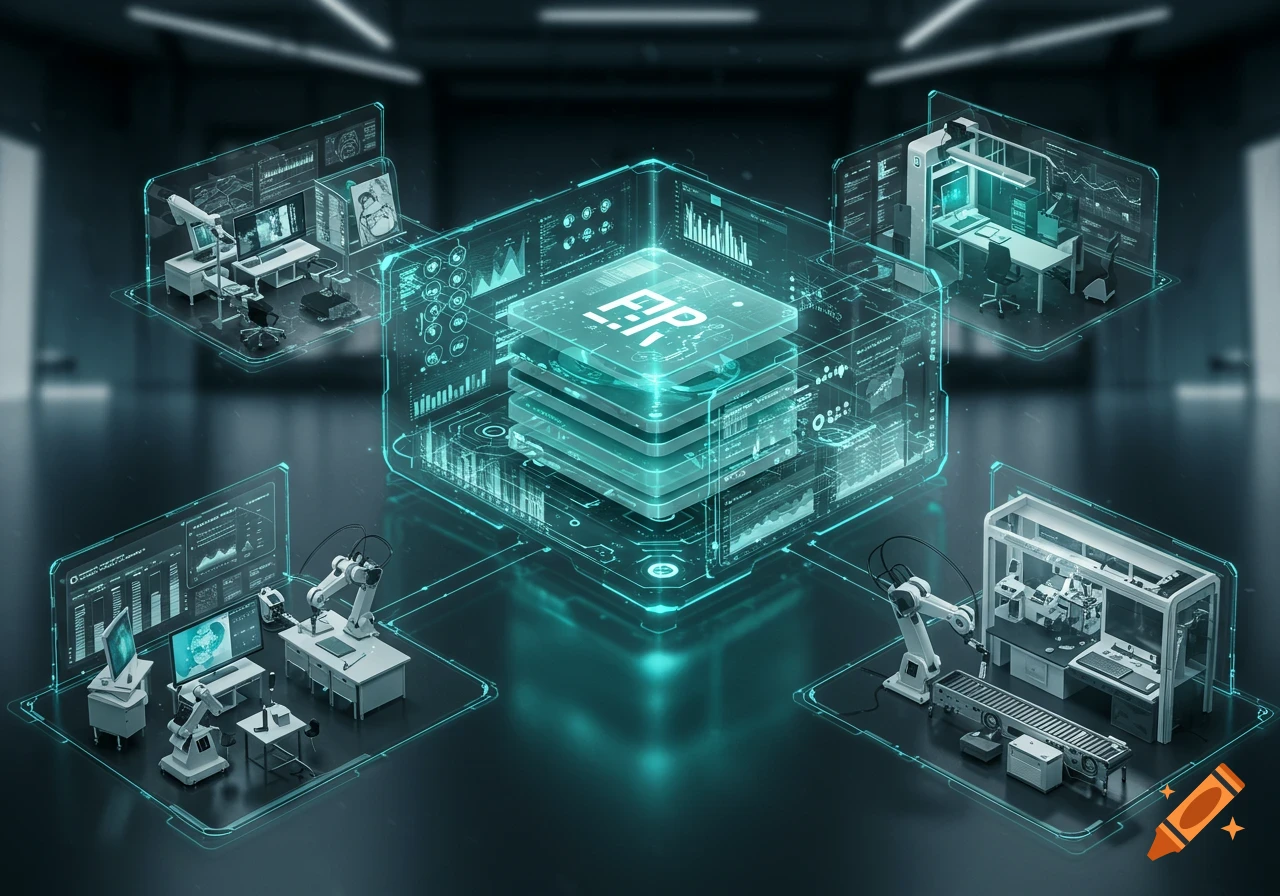

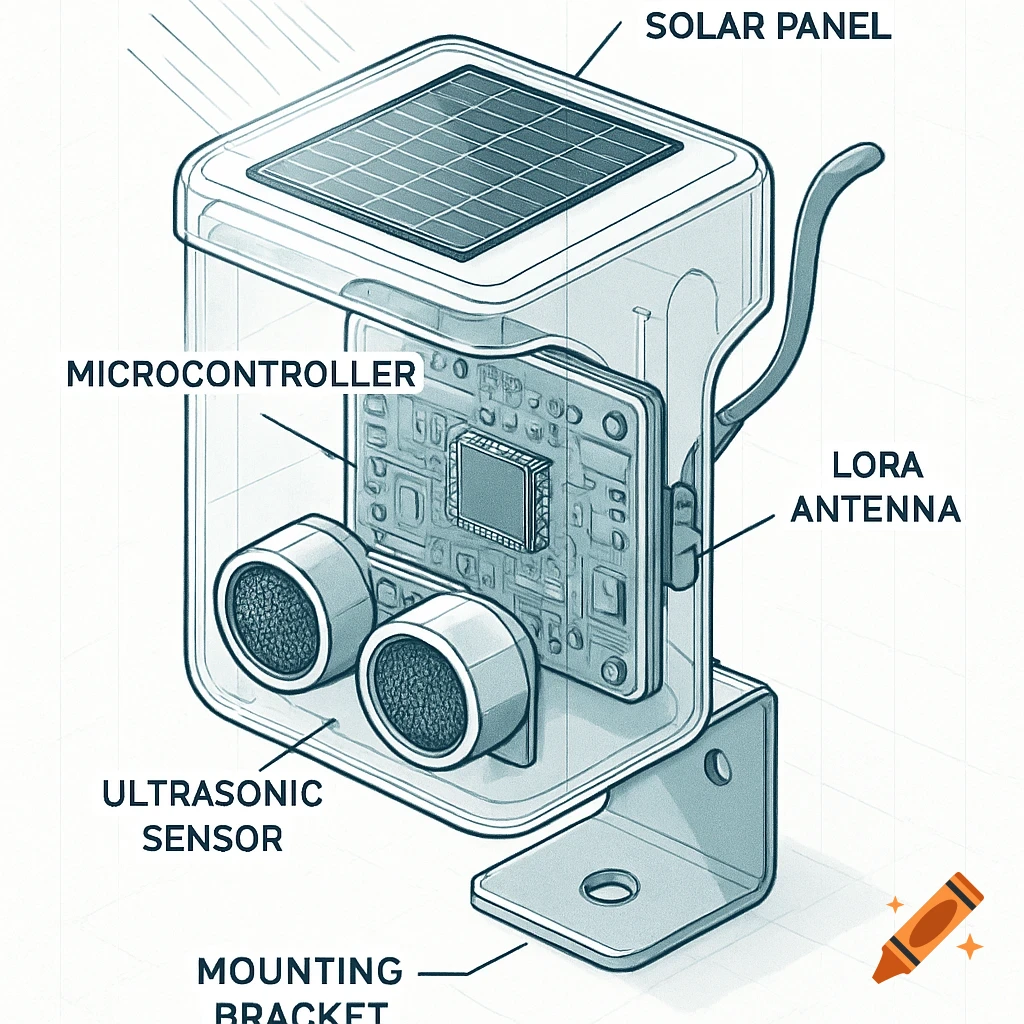

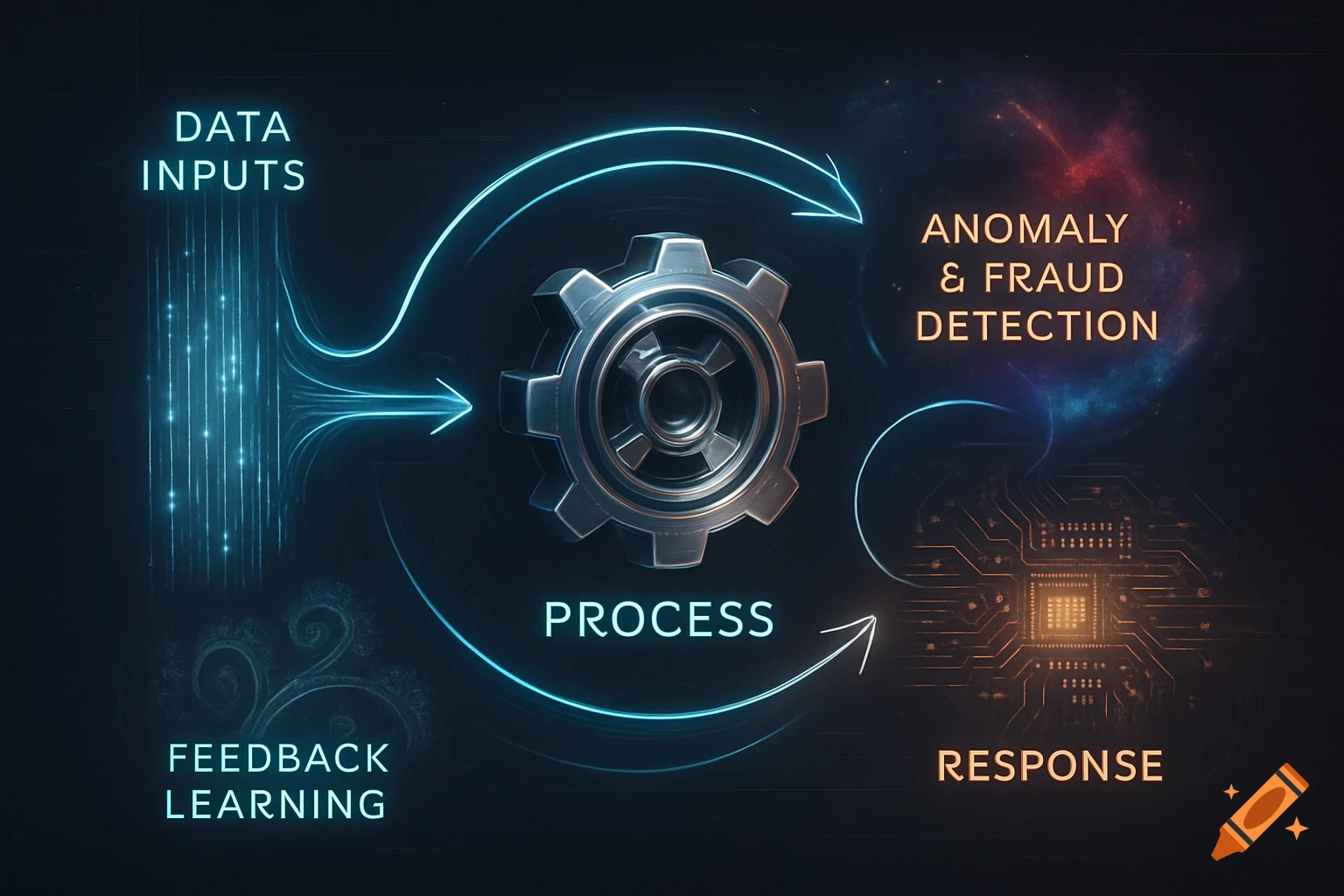

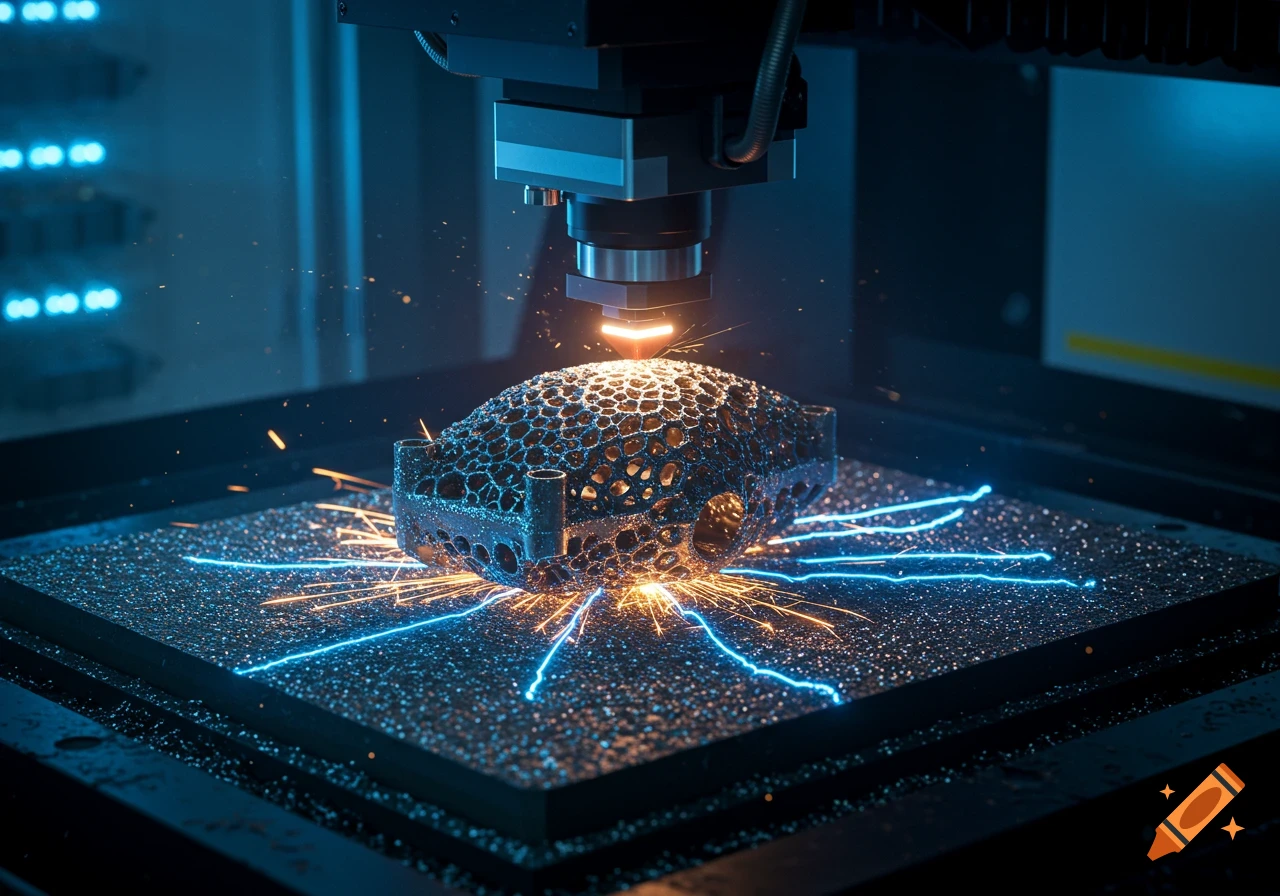

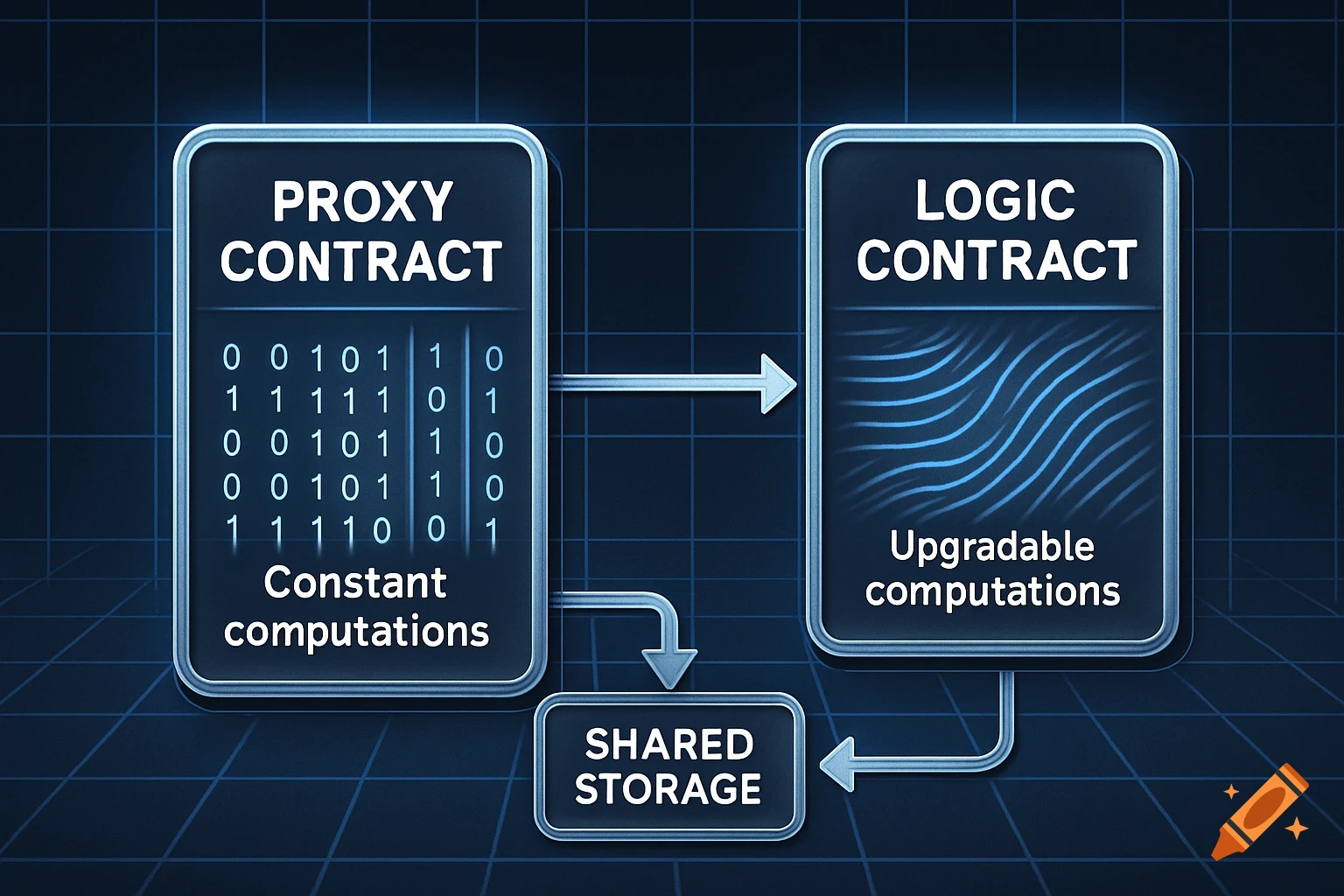

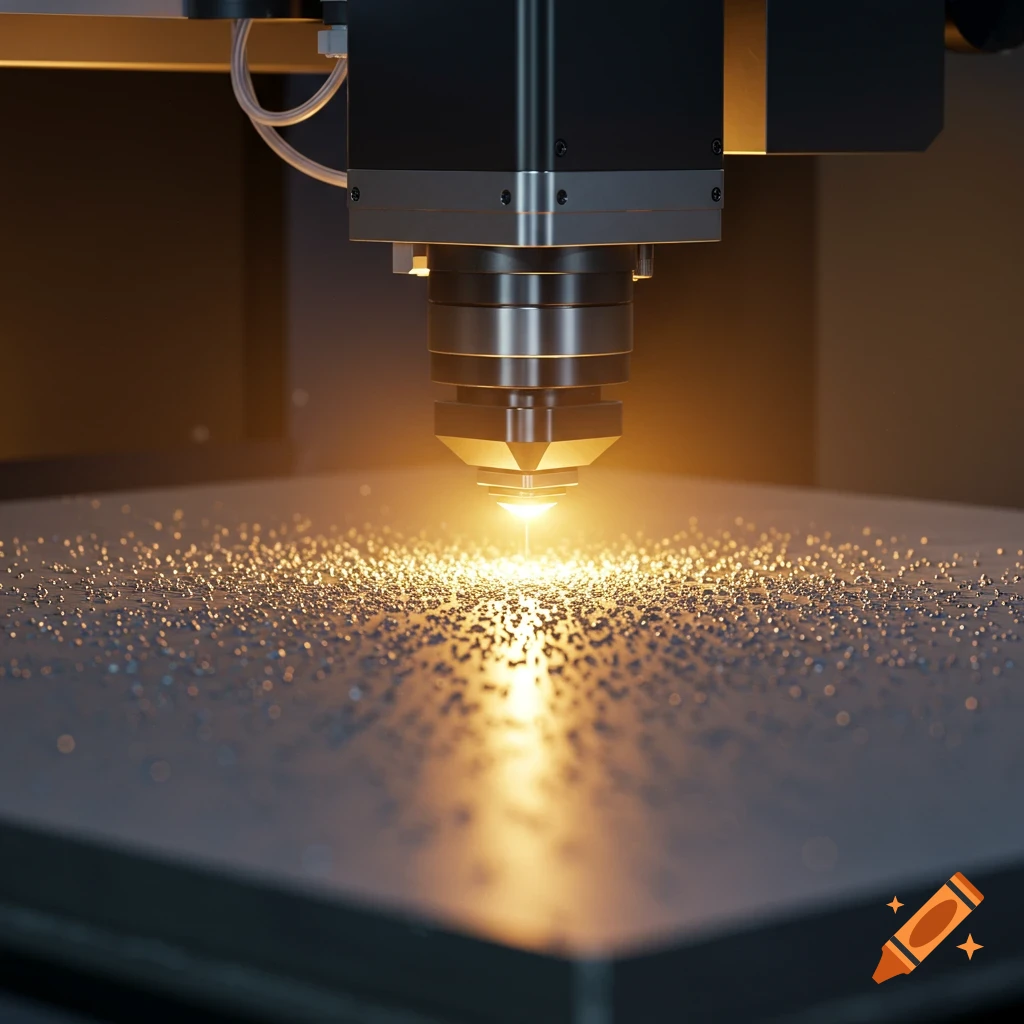

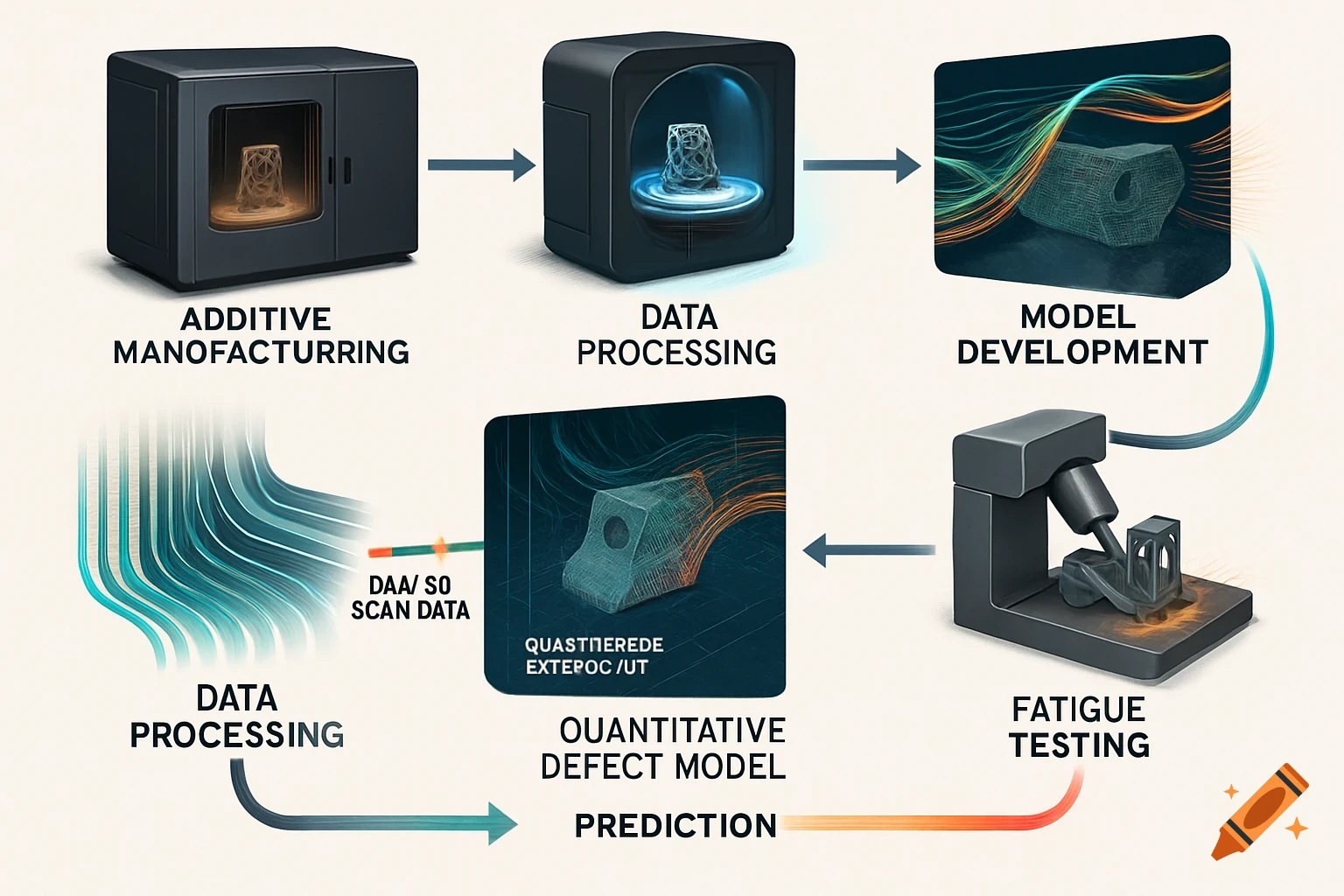

A block diagram illustrating a closed-loop workflow for additive manufacturing, data processing, model development, fatigue testing, and prediction.

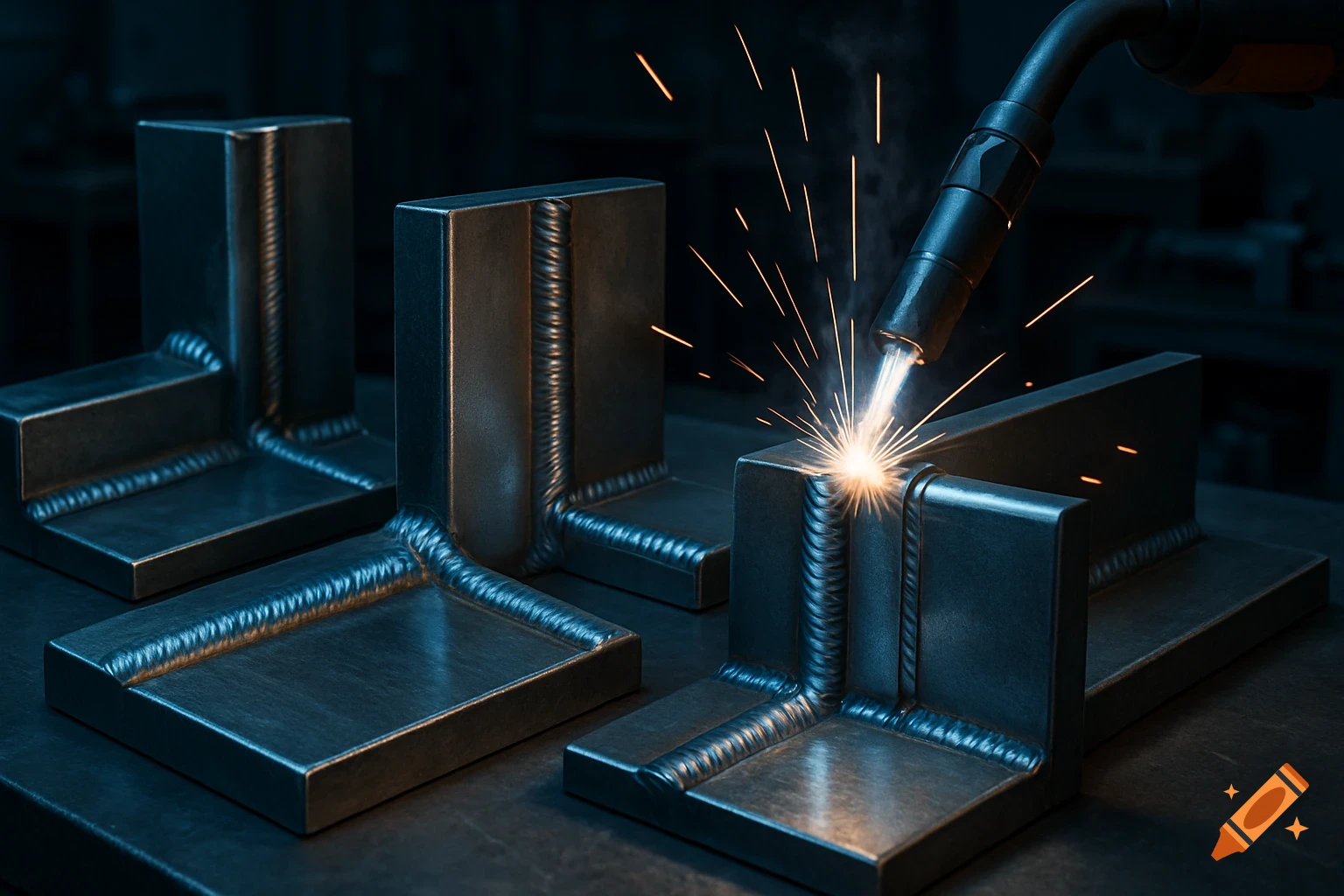

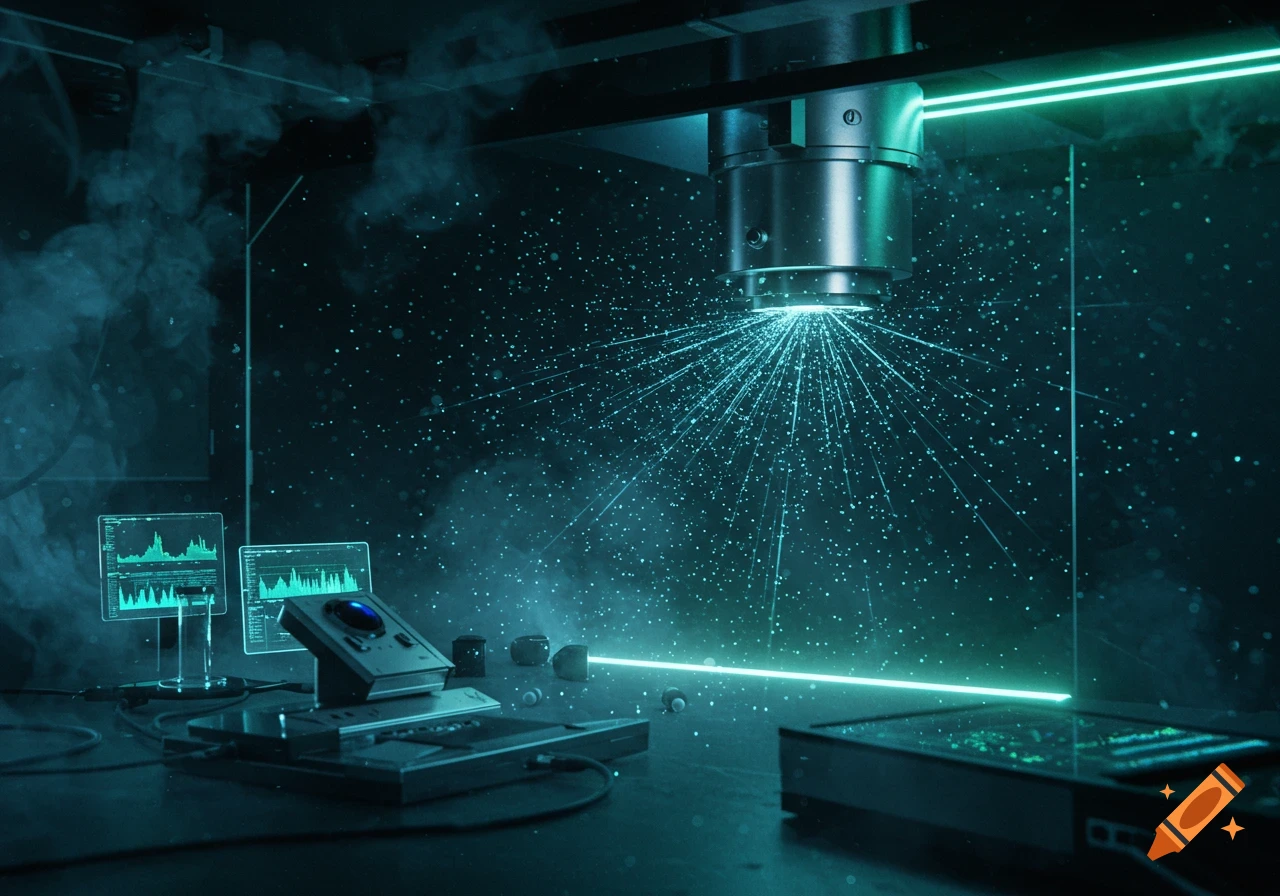

Block Diagram: Project Flow The block diagram illustrates the closed-loop, data-driven workflow of the project. • Additive Manufacturing: The process begins with the AM system, which produces the physical parts. • XCT Inspection: The as-printed parts are fed into an XCT scanner, which produces raw 3D scan data. • Data Processing: The raw XCT data is then processed to create a quantitative defect map. This map contains information on defect size, location, and shape. • Model Development: This quantified defect map is used as a direct input for the multi-scale fatigue model, which also incorporates other material data. This is the central computational task. • Fatigue Testing: A portion of the physical parts undergoes destructive fatigue testing to generate experimental data on their performance. • Validation & Refinement: The experimental data is used to validate and refine the predictive model. • Prediction: The final, validated model can be used to predict the fatigue life of new, untested parts, completing the loop and enabling virtual qualification. See more